Step 3 : Equipment design

Once we have determined the types of equipment required and the quantity of material flowing through them, we need to do detailed design of each equipment. In this ethyl acetate production process it could involve determining the exact size of reactor required to make the desired quantity of products at lowest cost.

Now we will take you to a different company to explain the Equipment Design step so you can see a variety of chemical processes.

Welcome! This company is a leading manufacturer of industrial chemicals. You will be working on an assignment with their chemical engineering design team.

Company wants to replace an old distillation

column which separates methanol

and water from a mixture, with a new

column of greater capacity. Your team will

be designing this new column.

Equipment design

Detailed design of equipment used in the process, which meets

requirements (like production rate) at lowest cost

What is equipment design?

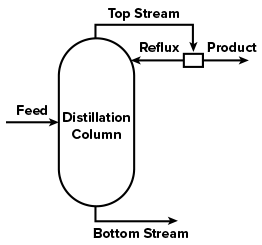

10,000 kgs of a mixture of methanol and water will be supplied to the distillation column per hour, out of which methanol will be 80% (8000 kg/hr) and water will be 20% (2000 kg/hr).

Distillation column needs to separate methanol from the mixture such that the product stream coming out from top of the column should have 7920 kg/hr of methanol while only 20 kg/hr of water.

Your team has found 6 suitable reflux ratios for this column. Using engineering software you need to find number of trays required in the distillation column for each of these reflux ratios to separate methanol and water in the desired way as above.

Team needs the number of trays to find cost of the column for each reflux ratio, and thereby find the ratio corresponding to minimum cost of column.

(Distillation here is a continuous process so kg/hr is used to indicate quantity of mixture entering and products leaving the column per hour)

Start Working

You will now begin working on the software for finding the number of trays. This assignment should ideally take 5 minutes.

How to find number of trays?

Input

Enter the feed mixture and product stream conditions as provided, into the engineering software.

Run calculations

Run the software for the 6 reflux ratios given, without changing rest of the input values.

Output

Software will calculate and give number of trays required for each reflux ratio to achieve the desired methanol separation.

Got it!

SOFTWARE

The following values you have entered are incorrect. Please refer to the assignment details and enter the correct values.

Try Again View Correct Answer

Enter necessary values in the Input form then run calculations for different reflux ratios to generate results.

23 trays are required at the reflux ratio of 1.2 to achieve the target composition of 7920 kg/hr methanol and 20 kg/hr water in the product stream.

20 trays are required at the reflux ratio of 1.4 to achieve the target composition of 7920 kg/hr methanol and 20 kg/hr water in the product stream.

17 trays are required at the reflux ratio of 1.6 to achieve the target composition of 7920 kg/hr methanol and 20 kg/hr water in the product stream.

15 trays are required at the reflux ratio of 1.8 to achieve the target composition of 7920 kg/hr methanol and 20 kg/hr water in the product stream.

14 trays are required at the reflux ratio of 2.0 to achieve the target composition of 7920 kg/hr methanol and 20 kg/hr water in the product stream.

13 trays are required at the reflux ratio of 2.2 to achieve the target composition of 7920 kg/hr methanol and 20 kg/hr water in the product stream.

Please run calculations for all available reflux ratios then submit report

Result report for the team

| Reflux Ratio | 1.2 | 1.4 | 1.6 | 1.8 | 2.0 | 2.2 |

| Number of Trays | 23 | 20 | 17 | 15 | 14 | 13 |

10,000 kgs of a mixture of methanol and water will be supplied to the distillation column per hour, out of which methanol will be 80% (8000 kg/hr) and water will be 20% (2000 kg/hr).

Distillation column needs to separate methanol from the mixture such that the product stream coming out from top of the column should have 7920 kg/hr of methanol while only 20 kg/hr of water.

Your team has found 6 suitable reflux ratios for this column. Using engineering software you need to find number of trays required in the distillation column for each of these reflux ratios to separate methanol and water in the desired way as above.

Team needs the number of trays to find cost of the column for each reflux ratio, and thereby find the ratio corresponding to minimum cost of column.

(Distillation here is a continuous process so kg/hr is used to indicate quantity of mixture entering and products leaving the column per hour)

Got it!

How to find number of trays?

Input

Enter the feed mixture and product stream conditions as provided, into the engineering software

Run calculations

Run the software for the 6 reflux ratios given, without changing rest of the input values.

Output

Software will calculate and give number of trays required for each reflux ratio to achieve the desired methanol separation

Got it!

Time is up!

This assignment could have been solved within 5 minutes. You can still continue to work on it, though deadlines are important in industry.

Cost

| Reflux Ratio | 1.2 | 1.4 | 1.6 | 1.8 | 2.0 | 2.2 |

| Number of Trays | 23 | 20 | 17 | 15 | 14 | 13 |

| Cost | 195000 | 170000 | 155000 | 150000 | 160000 | 175000 |

Theory

Higher reflux ratio

Higher energy cost

(More energy needed to heat

larger amount of reflux liquid)

Higher number of trays

Higher material cost

Conclusion

Cost of the column is minimum when

reflux ratio is 1.8 and number of trays is

15. So distillation column will be

constructed using this combination.

Your team has found cost of

distillation column for different

combinations to be as above

You have reached the end of this tour. Thank you for joining us. We hope to see you again soon!

Exit Tour

Exit Tour

Back

Back

About distillation column

About distillation column