Detailed design

After 'Conceptual design' comes 'Detailed design' stage. Selected 'Two flexible fingers' concept is further developed into a detailed design, with exact dimensions for all the parts, which can be used for manufacturing it.

To explain the Detailed Design step we will take you through a different industrial example so you can see a variety of mechanical products

Now you will be working with the engineering design team of an automotive company manufacturing a wide range of cars, SUVs, vans and trucks

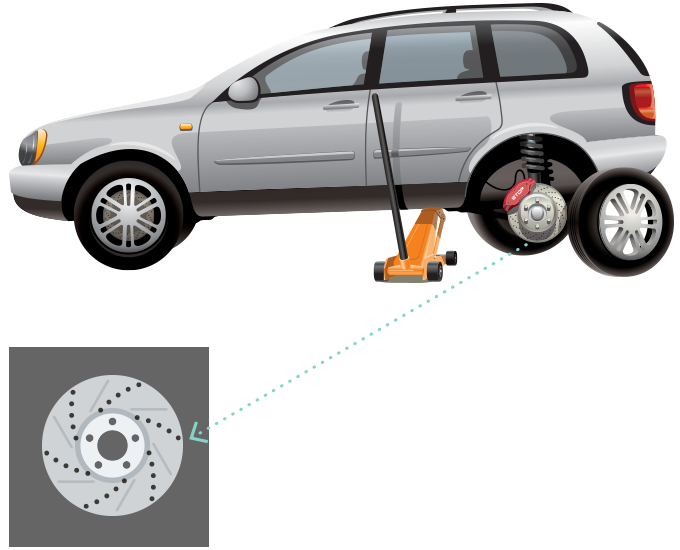

Company is developing a new model of their

car with improvements in the brake system.

You will be working on the detailed design of

brake rotor for this model.

* This example is on product modification

Detailed design

Step 1: Design generation

Determining product dimensions, material and

manufacturing process

* Note: Detailed design is done when developing new product as

well as modifying existing one

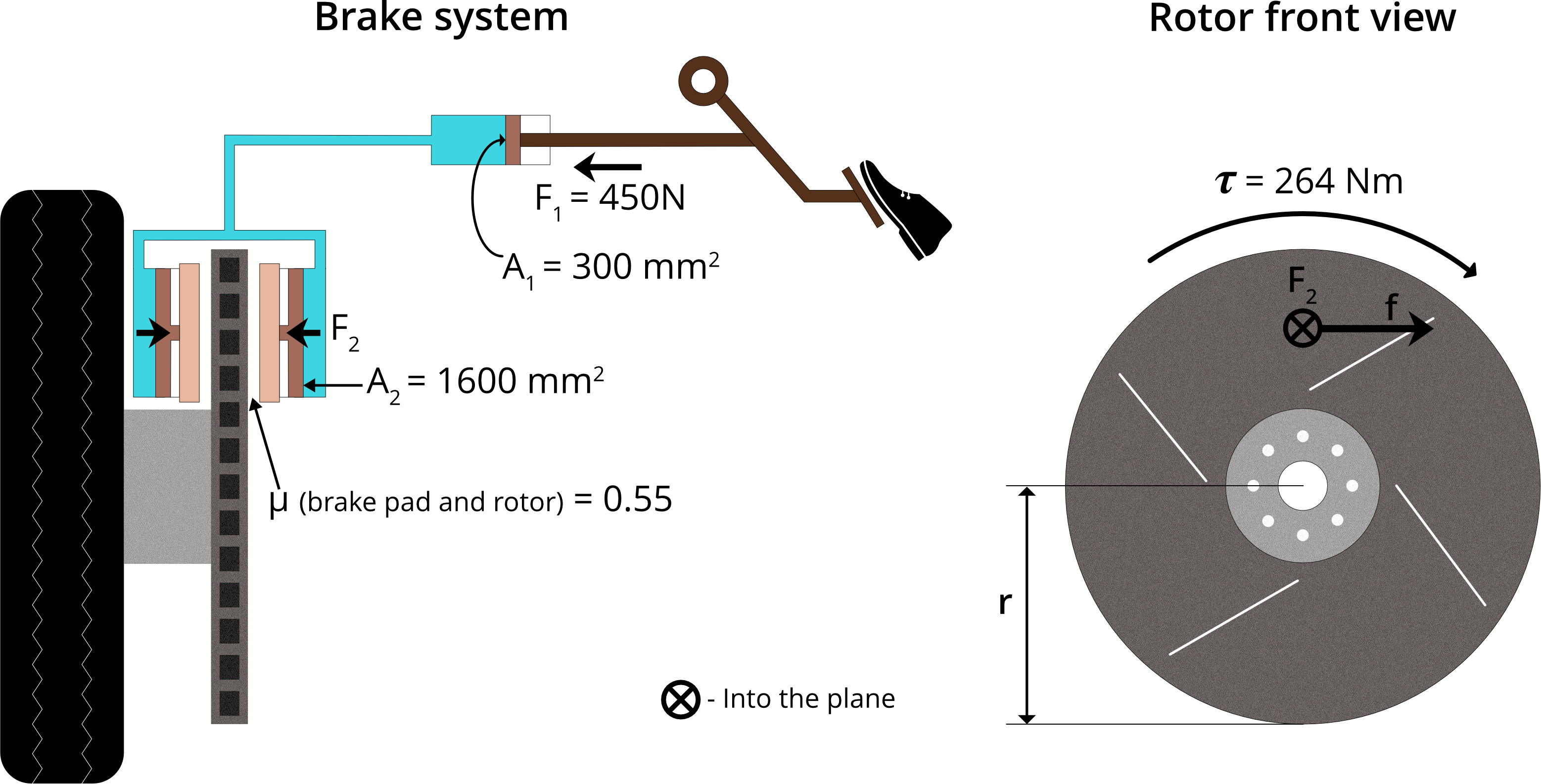

You need to find minimum radius of rotor (r) needed as

per following requirements:

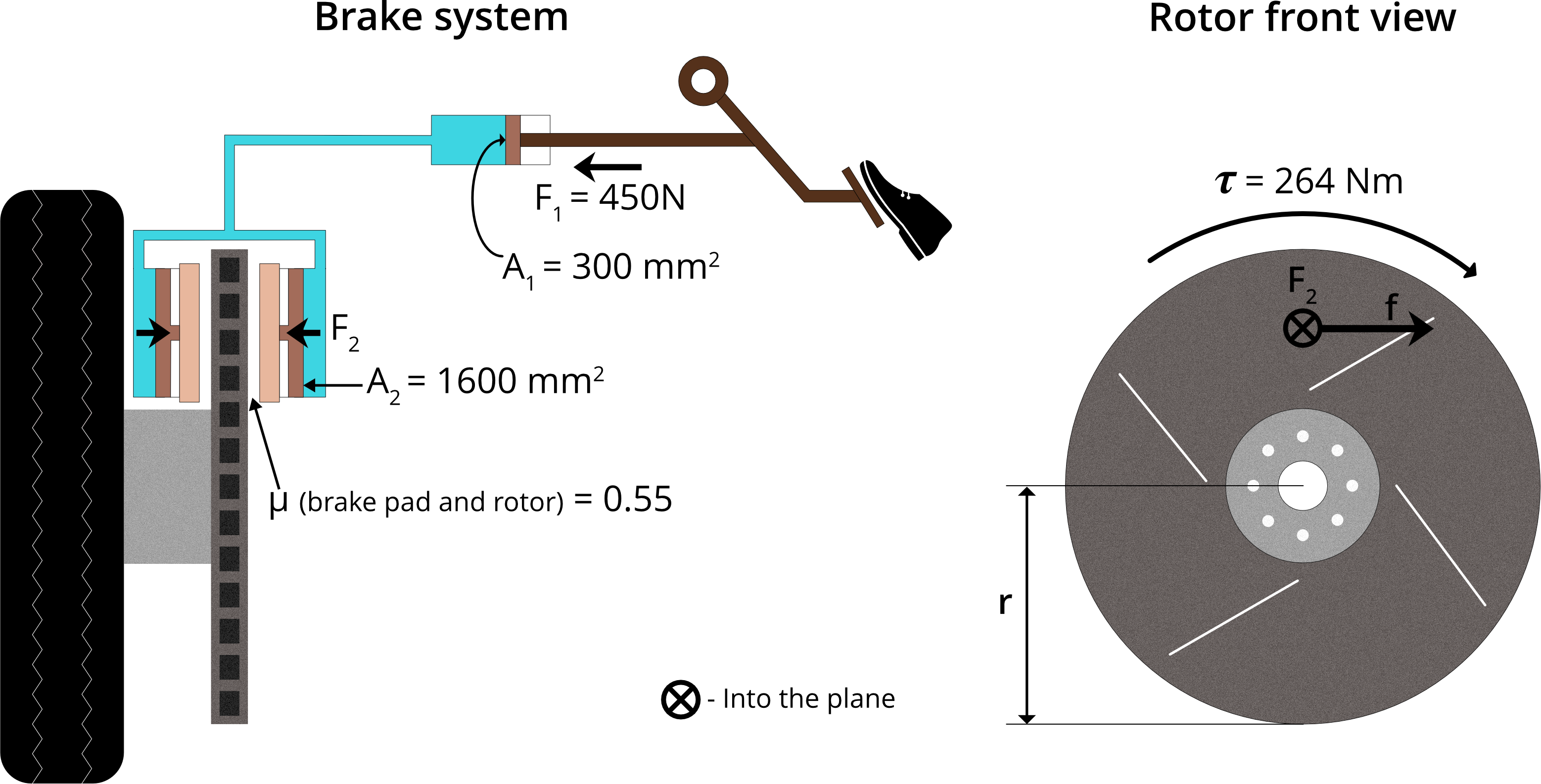

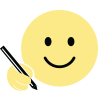

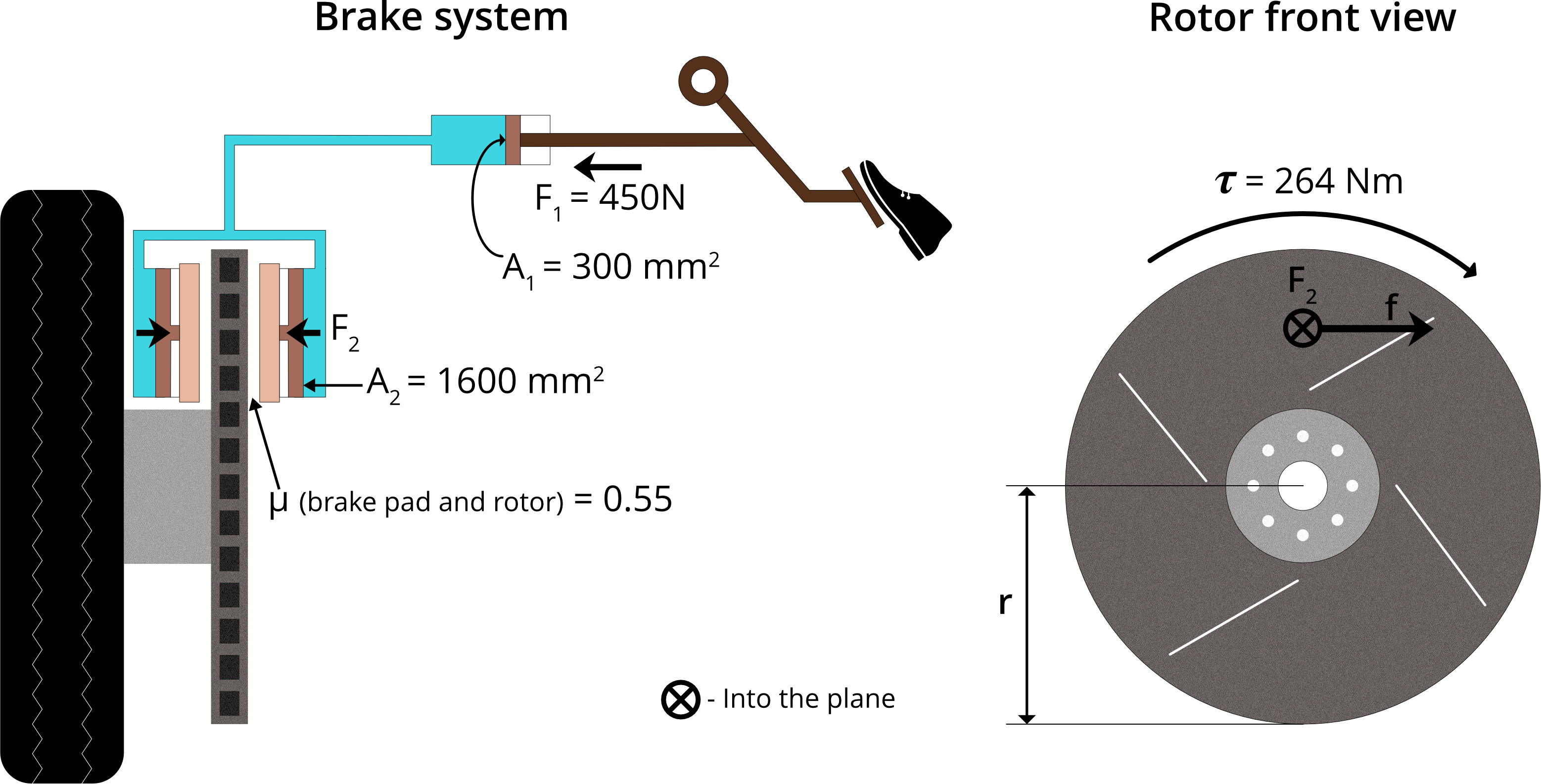

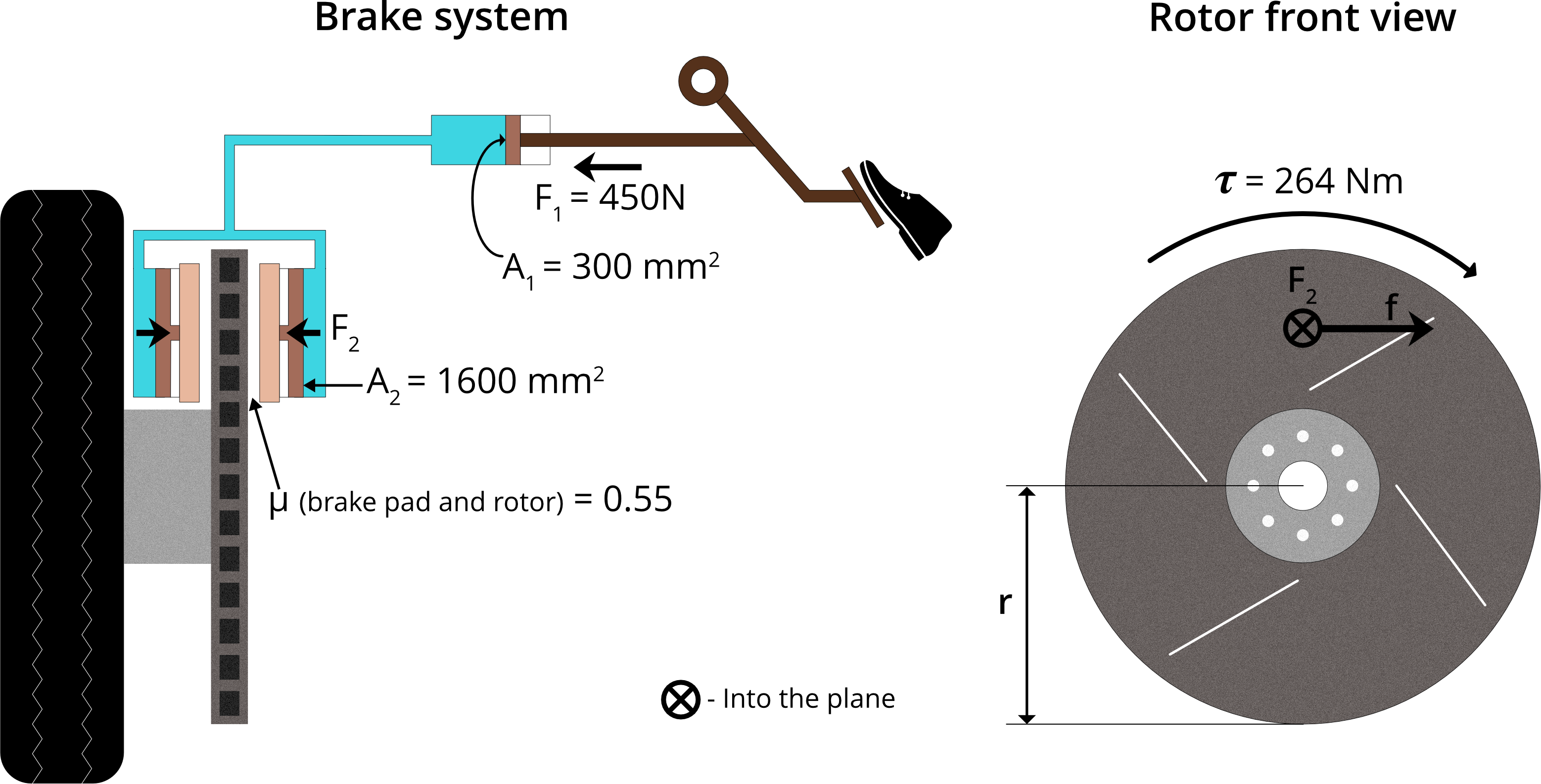

When driver presses the pedal, consider force exerted on master cylinder (F1) = 450 N

We will use our standard master and slave cylinders

where cross-sectional area of

Master cylinder (A1) = 300 mm2

Slave cylinder (A2) = 1600 mm2

Rotor material will be cast iron, so friction coefficient

between rotor and brake pad (µ) = 0.55

To stop car in desired way, minimum torque required

from friction between brake pads and rotor (τ) = 264 Nm

(Assume brake pads are very small compared to rotor

and close to rim of rotor to use radius of rotor “r” in

torque formula.)

Start Working

You will now begin working on the rotor radius calculation. This assignment has a duration of 10 minutes.

How to find rotor radius?

When brake pads press against the rotor they each exert force “F2” normal to the circular face of rotor and friction force “f” parallel to its circular face. Friction force produces a torque “t” in the opposite direction of rotor’s rotation causing it to stop.

Step 1

Find force “F2” exerted by fluid on piston of each slave cylinder, using Pascal’s

law and given “F1”, “A1”, “A2”

Step 2

Find friction force “f” exerted by each brake pad on rotor, using “F2” and given “µ”

Step 3

Find “r”, using total friction force on rotor and given “τ”

Let's get to work! Video and instructions on the right will explain how to solve this assignment. On proceeding you will be taken to your workspace to work on this.

How to find rotor radius?

When brake pads press against the rotor they each exert force “F2” normal to the circular face of rotor and friction force “f” parallel to its circular face. Friction force produces a torque “t” in the opposite direction of rotor’s rotation causing it to stop.

Step 1

Find force “F2” exerted by fluid on piston of each slave cylinder, using Pascal’s

law and given “F1”, “A1”, “A2”

Step 2

Find friction force “f” exerted by each brake pad on rotor, using “F2” and given “µ”

Step 3

Find “r”, using total friction force on rotor and given “τ”

Hint

Hint

Step 1

By Pascal’s Law

F1/A1 = F2/A2

Step 2

Friction force exerted by each brake pad on the rotor

f = μ x F2

Step 3

Torque on the rotor due to friction from the two brake pads

Ï„ = r x total friction force on the rotor

= r x 2f

Hint

Hint

Friction force on rotor by single brake pad (f) = μ x F2

Total friction force on rotor (fT) = 2f

(as there are two brake pads, one on both sides of the rotor)

Time is up!

This assignment could have been solved within 10 minutes. You can still continue to work on it, though deadlines are important in industry.

3D Model Design

From the initial data (minimum radius, thickness), engineer

makes a 3D Model of the rotor using software

This is a base design which will

further be analysed and optimised.

Back

Back

About Brake System

About Brake System